Immediately after the fuselage was transported to the hangar on day 2 of the move, wing attachment commenced. It took about 20 minutes, each side, to place the wing and slip the bolts in (not including torquing). There were no major issues. With just two people, it was quite manageable. We used a padded step-stool as a "third person" help hold the wing in place for the left side and the cradle for the right side.

Here we are taking the left wing from the cradle.

Moving left wing into position.

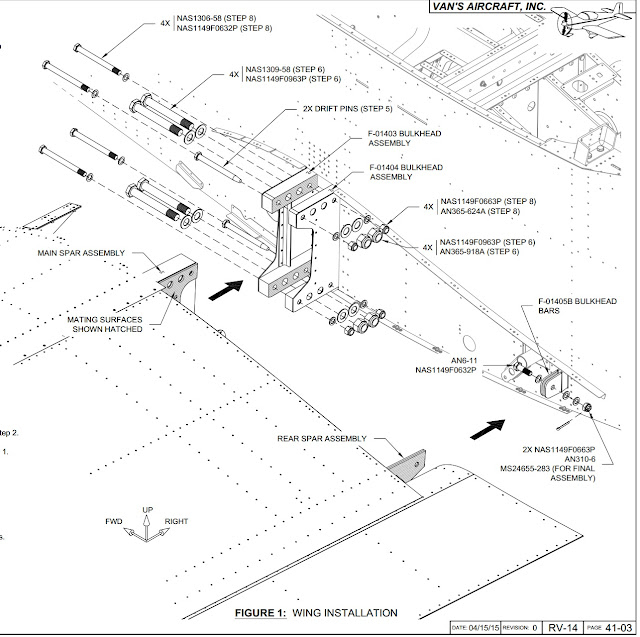

Slipping the drift pins in. My friend rocked the wing gently whilst I aligned the holes and slipped the pins in.

Here are the drift pins. I obtained these drift pins from my friend, who lives south of me and completed his own RV-14A. He ground off the threads and tapered them.

Completing the bolt placement.

There are 8 bolts per side, 4 on top, 4 on bottom. Four AN9-size each

necessitating 66.6-83.3 ft/lbs and four AN6-size each requiring 13.3-15.8

ft/lbs. There is also a AN6-sized bolt with a castellated nut on the rear spar.

Left wing in place. At this point, the aircraft would be good for some spins...and that's about it.

Next the right wing was attached. For this side we used the cradle as our "third person'.

Here's something to be wary of. The web on the F-01404 Aft Center Section Bulkhead was caught by the thread of one of the AN6-size bolts when it was placed. This caused the web to bend (left). When the nut was placed and torqued down, the web resolved itself flush (right).

The bird has wings! However, in this configuration, there would be very little lateral stability!

All bolts lined up perfectly after a gentle application of wing rocking. Only a rubber mallet and wood block were used to tap the lubricated bolts into place. The bolts were at ambient temperature of just under 80 degrees F and lubricated with liquid Boelube.