Work on riveting the non-skin related items on the mid fuse lower structure progresses.

There are a couple of ribs, F-01417-L/R, that get F-14100 routing angles (for future wiring, per a recent builder's query to Van's). It's easy to squeeze the upper and lower rivets, but the middle rivet is just a bit too long for even my

4" deep yoke. I don't have a rivet set for AN470AD3 rivets, but I do have a squeezer die and a strategically drilled 0.187" hole in a

footed bucking bar. Couple of wacks with the

back rivet set and all's well. Note that so far only 8 of the 10 routing angles are used. I see no other place in the remaining fuselage plans where the last 2 are used.

The F-00016-L/R step attach weldments represent an improvement over previous models: The steps are not riveted to the frame but rather are bolted on and removable. The weldments get riveted to the baggage ribs first. These rivets are a bit difficult to get to. The plans call for Cherry blind rivets in the recessed spots and gives the options of Cherrys (ies?) in all spots.

Turns out that they were all accessible with my two tungsten bucking bars (a.k.a., Mr. T) except for the lower, forward-most one. I have a

very small footed bucking bar that could reach it, but it lacked mass and it was clear that the AD4 rivet was reaching incipient work-hardening, so I removed it and went with the Cherry.

This tungsten bucking bar would have made simple work of that one rivet, but for $230, I'll stick with the Cherry.

Using the

angled Mr. T to hit the upper inset rivet (left). And the

rectangular Mr. T for the others (right). The gray primer represents spot priming of the countersunk nutplate holes and final drilled 1/4" bolt holes.

The one Cherry is evident (spot priming is visible and was necessary after removing attempted AD4).

Left weldment's shop heads (left). Right weldment's shop head (right). Some spot priming will be necessary where the bucking bars ate the powder coating off the weldments.

The side frame assemblies get riveted to the side frame brackets with the step attach weldments and doublers. The plans call for using LP4-3 pull rivets in 3 places.

However, I was able to squeeze all 5 rivets on both assemblies using my

4" deep yoke without issue. Taping the edges of the yoke helps prevent scratching the parts.

The step attach assemblies then get mated to the baggage ribs at the weldments and doublers.

These are tough rivets to set. In fact, these are the ones that seem most reasonable as Cherry, yet aren't suggested as such in the plans. I opted for squeezing them with my

4" deep yoke. Five of the six turned out well enough. One of them was clenched over (not shown). Ordinarily, I would have replaced it, but given the poor access, I figured I'd mess up the hole and decided to leave it.

Next, the step attach assemblies get riveted to the F-01425-L/R baggage ribs. Again, tight access. The plans call for 2 of the rivets on each weldment to be Cherry. However, I was able to squeeze all of them as AD4s using my

longeron yoke.

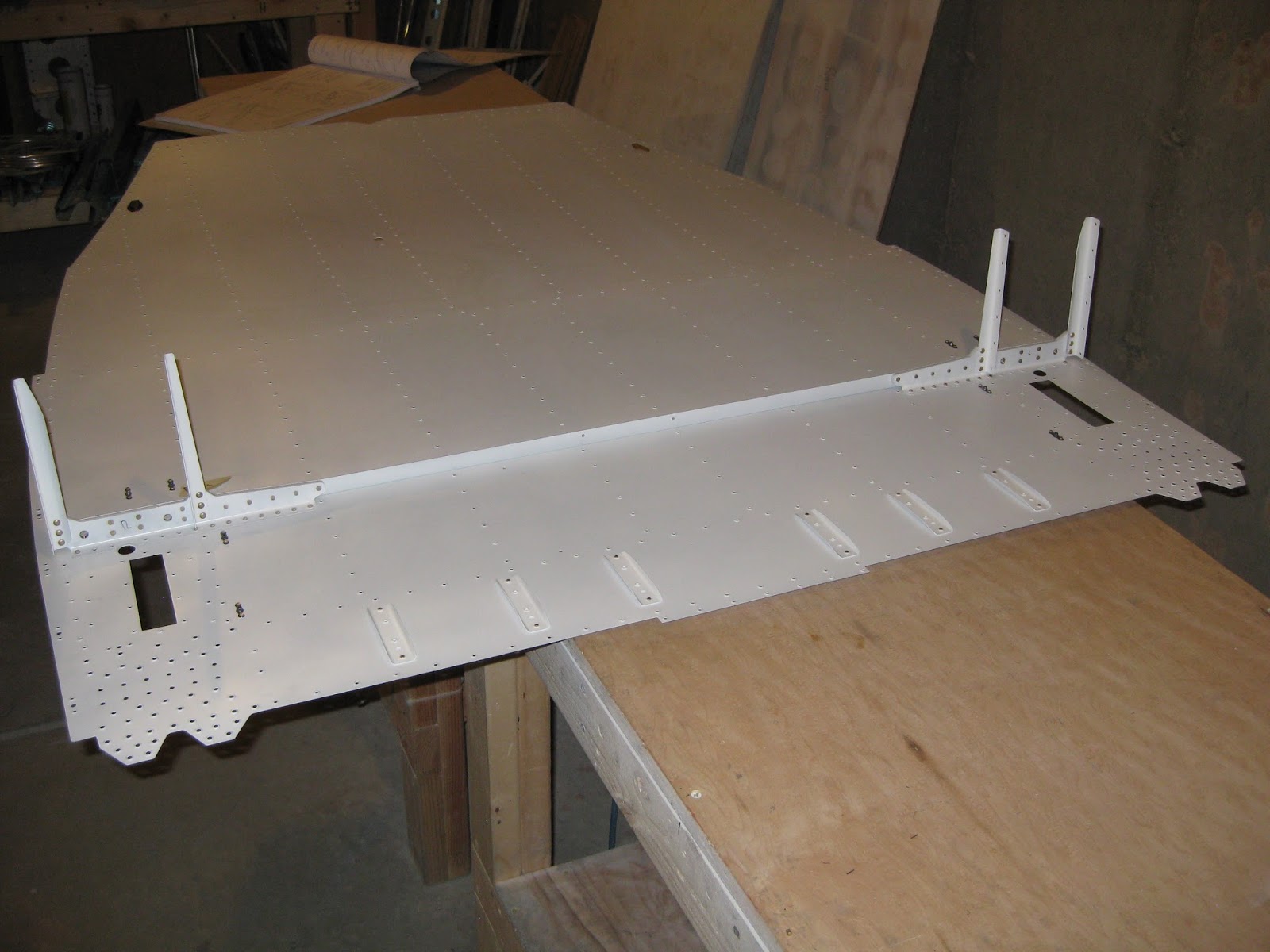

Completed step attach assemblies (sans nutplates on weldments).

Completed crotch strap assembly.

I'm building a tri-gear so my gear will attach to the forward bulkhead (rather than the firewall as for the tail-dragger). Thus, the plans require cutting the rectangular holes in the 0.040" forward bottom skins to match those of the 0.025" center bottom skin. I used a combination of my Dremel with a

reinforced cut-off wheel,

nibbler, files and sand paper to create those two holes. The holes aren't perfect, but no one will see them and they'll function just fine as-is. They were rounded and smoothed down to mitigate cracking. The Dremel got away from me on the right skin necessitating a notching and subsequent smoothing to reduce skin stress.