I had the pleasure of building three right elevator spars before I finally was happy with what I had.

Spar #1 was messed up due to builder error: I didn't like how two tip assembly rib-to-spar AD4 rivets were sitting. When I went to remove them, I completely botched the procedure (it's tight quarters in there) and the replacement rivets looked horrible (in fact, one went to an AD5). I deemed them unacceptable (see below), though two tech counselors disagreed with me. So I scrapped the whole spar assembly (spar, tip rib assembly, root rib and horn) in favor of a new one.

Update 19-Sep-20: On having the opportunity of building another elevator, it occurred to me that it may be better to not follow the plans' order of riveting. Thus, on page 09-16, I prefer replacing Step 2 with riveting the E-904 Tip Ribs to the E-00902-1L/R spars first, the riveting the E-903 Tip Ribs to E-904 and E-00902-1L/R. This allows for easy squeezer access to those rivets shown below.

Spars 2 and 3 related to the horn fitment.

Spar #2 went along just fine in the beginning. The tip rib assembly was a real pain to line up with the spar, but I managed to do it after several hours of frustration. The horn was easily final drilled to the spar and root rib. Then the root rib was riveted to the spar. But, when I went to rivet the spar and root rib to the horn, the holes no longer lined up between the spar and horn! After spending a few hours trying to solve the problem, finding myself perplexed, I chalked it up to builder error and scrapped the whole spar assembly in favor of a third attempt. However, to see how the spar-horn holes would look, I final drilled the horn to the spar and root rib. The spar-horn holes were horribly oblong, as expected, and shown below (in executing the final drilling step, I now of course had #30 holes in the horn).

Spar #3 reused the horn from the second spar. This meant the horn had #30 holes in it and the spar and root ribs still had the corresponding #40 holes. For this third attempt I took a different approach. I figured if I riveted the root rib to the spar,

then final drilled the horn to the spar and root rib when cleco'd to the elevator skins, I could avoid any misalignment problems. See, because the root rib is flush riveted to the spar, in the plans riveting the rib to the spar is saved for after the horn is final drilled. So in my mind, there could be some lateral movement freedom of the root rib that wouldn't be present otherwise. Turns out, even after this sequence modification, I still had the same issue, as seen below. (The image below shows some trouble I had priming the third spar: My

HVLP gun was not setup right so it was spitting out too much primer.)

At this point, I was skeptical of the problem being builder error as I had no such issues with the left elevator and the first right spar and I didn't believe I was doing anything different. So I took a closer look at the three right spar assemblies I now had to see what differences I could find. See the images below.

So clearly, the right root rib from my second (not shown) and third spars were misshaped. On the second spar assembly, the problem manifested after the final drilling of the horn one doesn't rivet the root rib to the spar until after final drilling the horn to the assemblies. So, the root rib's movement isn't restricted at this point.

Upon consultation with Van's, they suggested I could bend the root rib to make it fit. However, I don't believe they fully understood my findings. Whatever machine is used to make that curve in the rib didn't put

the curve in the right place. It's as though the rib wasn't fully

inserted (or inserted too far) into the bending machine so the curve

happened slightly offset from where it was supposed to be.

Unfortunately, it isn't something that can simply be adjusted

with a bend (or if it is, the method for doing so escapes me). That

bend has to be "rolled out" (sort of like what one does with a tape

measure when you push the tape down on a surface).

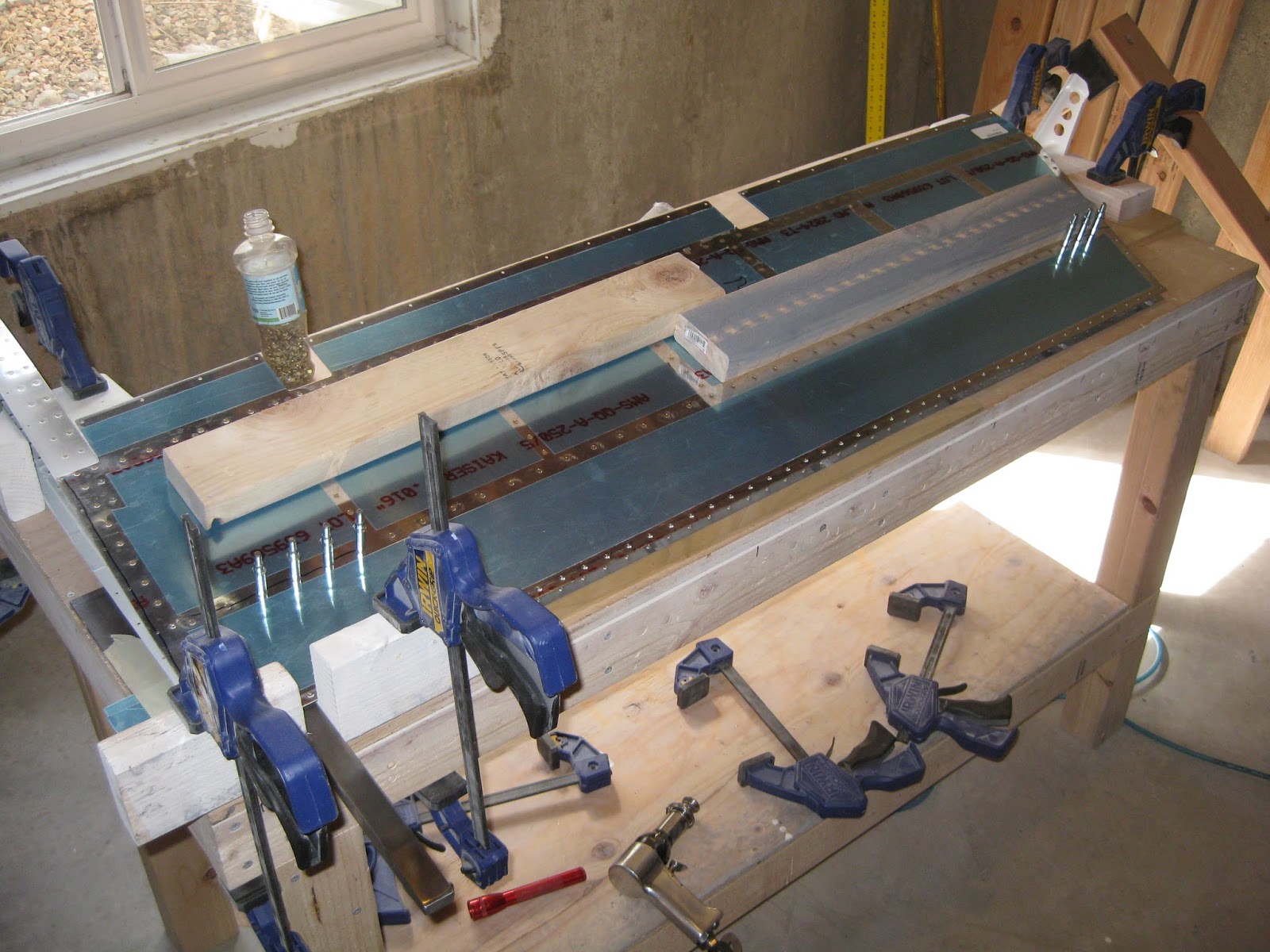

To make it work, what I did was cleco the

horn to only the root rib so the horn was free to move along the

spar (as free as it could given that the rib curve was

restricting it). Then I pushed, really, really, really, really

hard on the horn so I could manage to sneak in one silver

cleco. Then I used my punch to wiggle the horn closer to a

better alignment with the holes. I managed to get all six

clecos in, very tightly. However, I felt like the parts were under a lot of

stress, so I didn't want to end up locking in that stress when

riveting together. So I took the horn off in favor of a different approach.

On the root rib

I pushed really, really, really, really hard with strategically

placed wood blocks to try to change the curvature of the root

rib. Seeming like I might have, I put the horn back on and

using the same method as before, I convinced myself that the

parts weren't under stress (or at least, not as much as

before). Now, keep in mind I'm reusing a horn that already has

#30 holes in it. So I had to make sure that the #30 holes I was

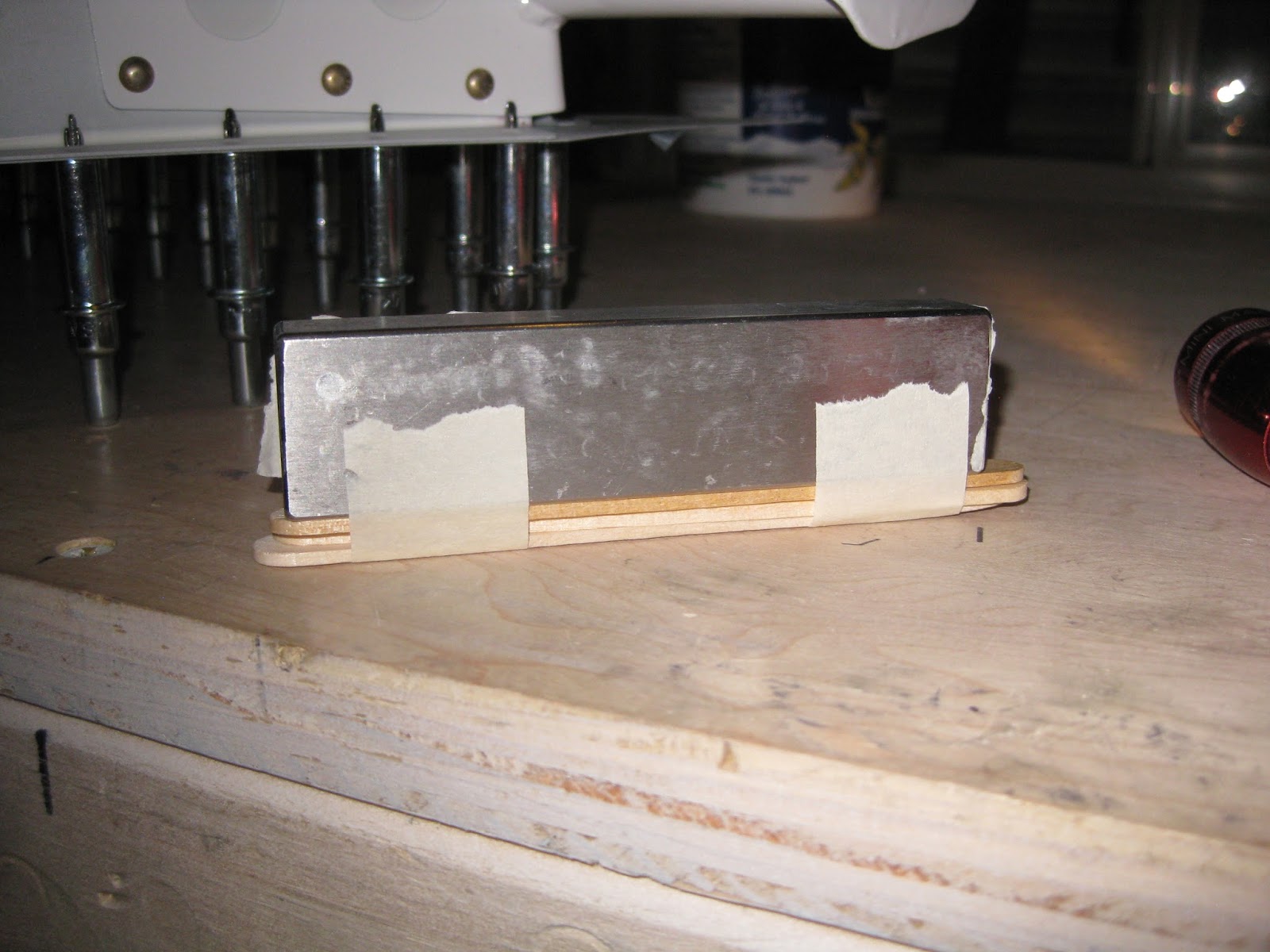

going to drill into the spar would be round as the spar had #40 holes. To do that, I had

to ensure that the #40 holes in the spar would at least be

tangential to the #30 holes in the horn (i.e., prior to final

drilling, the holes should look like what's on the left rather

than the right). Using my #40 punch, I visually confirmed this

desired outcome on all 12 holes.

When I final drilled the parts, I did not remove the entire set

of clecos to debur, rather I removed one at-a-time to debur.

This way I ensured I wouldn't lose alignment like what might

have happened on the second spar. Every hole was round and each

rivet slid in to its hole without resistance and not at an

angle. After riveting, the horn sits nice and flush on both the

rib and the spar. So, long story short, I now have this

wonderful sight 5 months after messing up the first spar.

Which is now ready for the trailing edge and foam ribs.

I hope this explanation made sense. For a problem that is essentially simple, it is surprisingly difficult to articulate it with a reasonable level of clarity.