For all of the rear spar rivets that needed to be bucked, on both the left and right elevators I had help, which made the process much easier. The plans have you hold off riveting a few of the bottom skin-to-rear spar rivets so that there is better access for sealing in the trailing edge foam ribs. I didn't have help for those remaining rivets, so I needed to come up with a way to hit them myself. The challenge being, as I had previously learned, keeping the special bucking bar from slipping off the rivet during bucking.

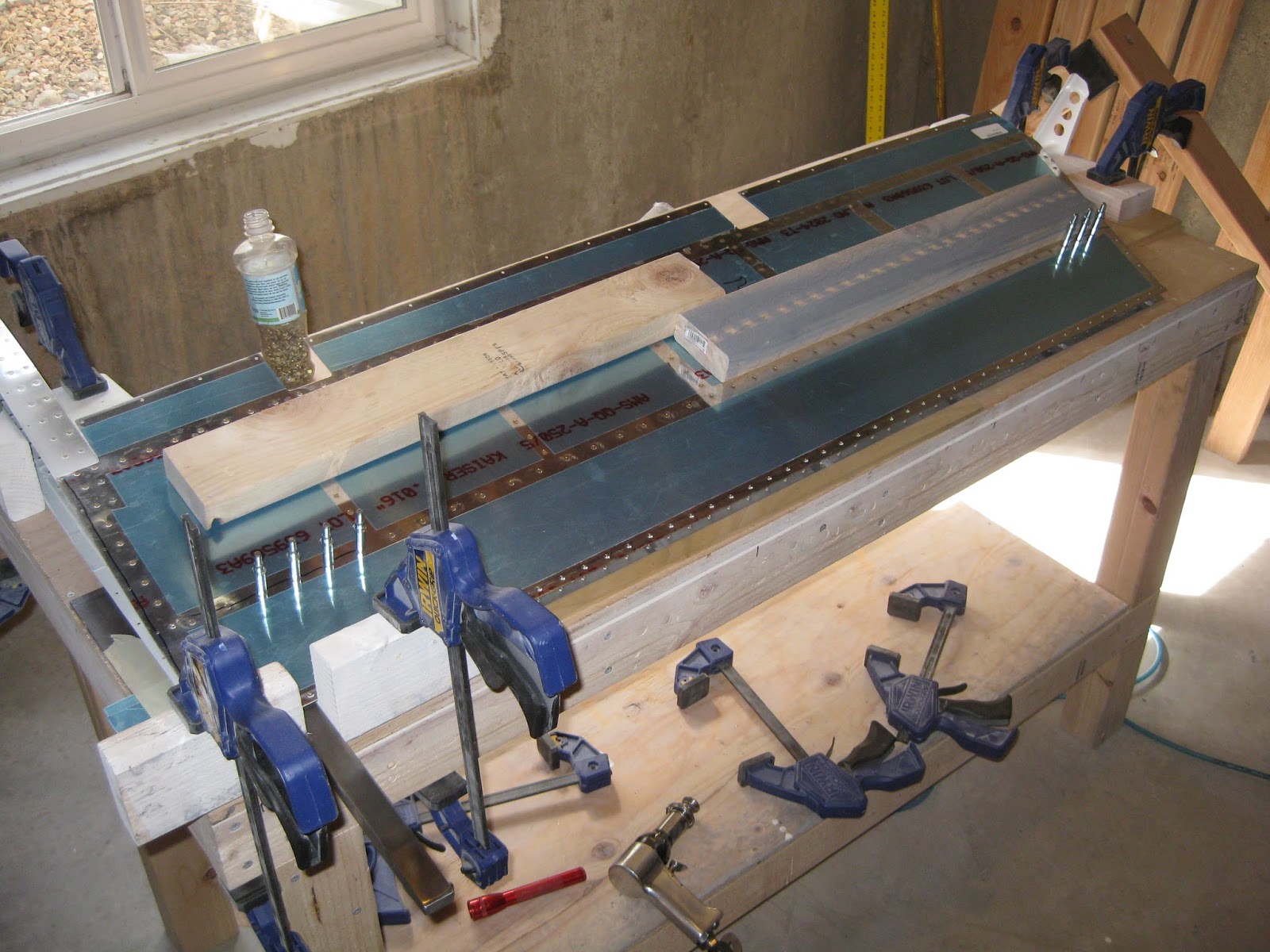

Here's what I came up with. Propping up the elevator with shims to prevent deforming skins as per plans, I locked the elevator in place with wood blocks clamped to the table against the tip rib assembly and horn then sandwiched the bucking bar in place with clamped wood blocks too. I would move the clamps and bucking bar as I progressed through the remaining rear spar rivets.

You can see my left hand pushing down on the bucking bar, with the steel plate underneath it acting as a fulcrum, so that the bucking bar pushing up against the shop head of the rivet.

Hitting the inboard-most rivet was a bit of a challenge with that root rib coming in at an angle.

No comments:

Post a Comment