It's a bit difficult to access the inboard gusset on the elevators. You have to lift the skin up (assuming you remembered to exclude the associated skin rivets earlier on 9-18) to present yourself with a restricted workspace to slide in a bucking bar. This is not a place you want to make a mistake (smile, bucking bar slip, etc.) as rivet removal would be a challenge. For example, I ended up with an AD4 on the left elevator.

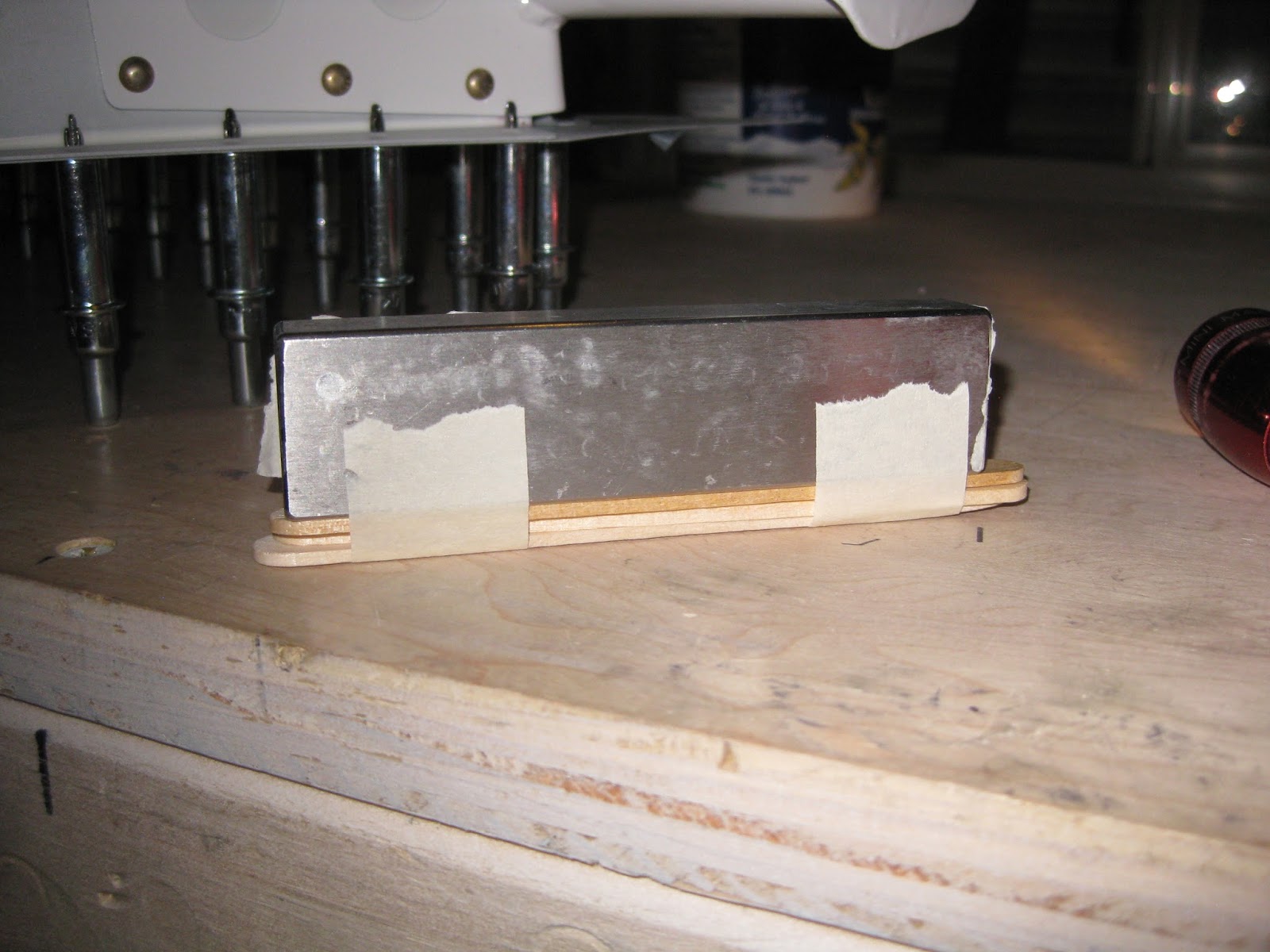

First thing to do is place some masking tape on the manufactured heads of the rivets to mitigate the rivet set from slipping and imposing a big toothy smile in the head. Next, use a bucking bar that is appropriately dimensioned for the task. I used Mr. T. as, when laid on one side, it lines up well with the lower gusset rivet. Then, to hit the upper rivet, I taped some Popsicle sticks to the bar so it was elevated enough to cover a well-formed shop head.

Here's what the inboard gusset looked like after bucking. Not too bad.

A similar exercise is done with the outboard shear clip. The trailing edge rivet has a slightly angled shop head, but entirely acceptable.

No comments:

Post a Comment