I don't plan to have a cushy interior, so as only to reduce weight. Thus, I plan to paint the interior and otherwise keep it bare. To that end, I have spent much time considering what paint to use for the interior. VAF is awash and such discussions. Options range from pricey JetFlex to cheap hardware store rattle can types.

I've decided that the following are important to me:

Thus, I've settled on the Rust-Oleum Hammered series of paint. It's $5.75/can pre-tax locally. The hammered finish gives a nice texture and helps hide surface profile irregularities and minor scuff and scratches. I tested the paint on some primed scrap aluminum. The paint is dry to the touch in less than an hour. Fingernail dents are easy at 24 hours cure, and harder at 48. The paint cures very, very hard after two weeks. It takes a lot of effort to scuff it. So it meets my, cheap, easy and durable criteria.

I've decided that the following are important to me:

- Low cost.

- Reducing application labor.

- Quick-and-easy touchups.

- Relatively high durability.

Thus, I've settled on the Rust-Oleum Hammered series of paint. It's $5.75/can pre-tax locally. The hammered finish gives a nice texture and helps hide surface profile irregularities and minor scuff and scratches. I tested the paint on some primed scrap aluminum. The paint is dry to the touch in less than an hour. Fingernail dents are easy at 24 hours cure, and harder at 48. The paint cures very, very hard after two weeks. It takes a lot of effort to scuff it. So it meets my, cheap, easy and durable criteria.

The paint comes in two flavors. One is in a plain rattle can. The other (about $2.50/can more) can be shot upside down which will be perfect for getting under the longerons. I've chosen the silver color, though it's a little darker than I'd like. The white was "too white" for me. All the colors are somewhat glossy. I figure if that's a problem later, I can hit the glossy areas with some clear flat spray to knock out reflection problems. An inexpensive solution is the name of the game here.

I've found that the hammered finish comes out much nicer if it is applied to a smooth surface. It turns out that some of my primed parts have primer that was mixed a bit thick (not enough water) so I got big droplets which dried before spreading and flowing on contact with the surface. I think this can be tended to by some passes with sandpaper prior to painting.

Here are some parts from Sections 42 and 39. Left pre-painting. Right painted.

These close ups really show the hammered finish.

This shows the gloss characteristics. Again, though I don't like it, if it's a problem, I can hit such areas with a clear flat to knock them out.

Here are some parts from Sections 42 and 39. Left pre-painting. Right painted.

These close ups really show the hammered finish.

This shows the gloss characteristics. Again, though I don't like it, if it's a problem, I can hit such areas with a clear flat to knock them out.

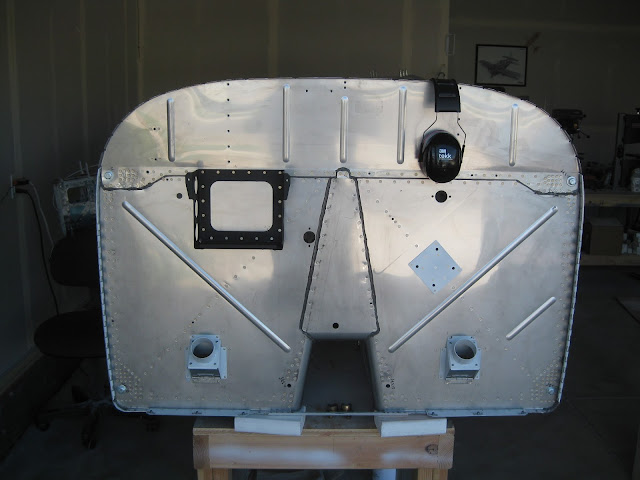

And for the heck of it, since I had leftover paint from painting the landing light cavities a couple of years ago, I decided to make the battery box black. I like how the rivets give some highlights to the part, though they'll be later obscured by the battery.

How’s that hammered finish Rustoleum holding up? Getting ready to use it albeit in very limited areas as I am using an interior and carpet (which I am hoping will help with cabin noise as well as look nice).

ReplyDeleteI used some hammered grey on the fuel selector plate and other exposes areas of the fuselage. I scratched off bits within a year. My buddy helped me spray most of the interior with JetFlex and it looks pristine five years later.

DeleteHey Lou. The paint has been holding up great. I've been quite pleased. Scratches occur infrequently and are easy to spot fix during the condition inspection. I usually fix one or two tiny areas each year. The interior still looks like it was freshly painted.

DeleteHi Anonymous. Sorry you had trouble with your original paint job though that's great that your second approach is working well for you.

Delete