Since I installed dual SureFly ignition in my airplane, having a fully electronic ignition means being thoughtful and deliberate about how those magnetos get their power, i.e., one needs a backup battery and a means to control how that battery is connected to the ignition and the main bus. The SureFly's STC points to the guidance in the install instructions on how the backup system should be designed. Below I outline my approach which closely follows that guidance.

In selecting the backup battery, I wanted something very

light, in front of the firewall and that could hold enough energy for at least an

hour of flight under non-ideal conditions (i.e., a tired or somewhat discharged battery). I didn't want to use the TCW backup battery because it's very expensive, large, seems difficult (and costly) to replace when the time comes and doesn't give me flexibility in controlling its behavior.

In my case, I decided that the EarthX ETZ5G battery would be a good fit, at 3.4 Ah and 1.15 pounds and no-load, fully-charged, nominal voltage of 13.2 V. This battery would ideally provide 3.4 hours of run time for a single SureFly, so factoring in non-ideal conditions, it seems more than adequate.

There were two reasonable locations to place the battery. One was above the main Odyssey battery on the ride side of the firewall. The issue with that location was that I'd need to drill into the firewall to mount the EarthX battery. I didn't want to add more holes, so I decided to mount the battery below my GPS antenna shelf on the left upper firewall by using a bolt on that shelf and two bolts that hold the AHRS tray to the backside of the firewall.

Below shows the EarthX battery

situated in the proposed location. I anticipate replacing this battery

every 5 years. Having the battery located here means it makes sense to have the backup battery connected to the left SureFly and the main battery connected to the right SureFly.

With my newly developed 3D CAD skills resulting from my larger oil cooler modification, I designed a mounting tray for the battery using OnShape

(EarthX didn't offer a tray for this specific battery). The design includes

provisions for riveting it together, holding tabs, mounting plate and

mounting holes for a circuit board whose design I'll explain later in

this post. Below is an isometric view and various images of the

design. My design was fabricated by SendCutSend for $57.06 shipped.

The design includes a plate that

attaches to the outboard hole of the GPS antenna shelf (which is really

the upper left outboard hole of the AHRS tray) and the bottom two holes of the AHRS tray

(shown on left image below). SendCutSend doesn't do joggles, so I did

that one myself. Then I used clay to locate and drill the upper bolt hole.

That's the left image below.

After the parts were primed, the battery tray was riveted together then riveted to that plate as shown in the right image below. Then the battery was mounted as shown on the lower image below. Note, you can also see the initial revision of a circuit board I designed, the final revision of which I'll explain next.

Note: In the above image, you can see how I grounded the battery. I used a 1/16" piece of aluminum to bolt to the negative terminal and then a screw into the battery tray. Since the tray is riveted to the mounting plate, which itself is bolted to the firewall, this seemed a great approach rather than using a wire.

Having a backup battery requires one to have some means to control how its energy is accessed and replenished and having a means to isolate that battery from the main bus so that it doesn't power the main bus and only powers what it's intended to power.

My requirements for the backup battery controller circuit board that I would design included:

- Backup battery can't provide energy to the main bus.

- Backup battery charging available by the main bus.

- Pilot can control when the backup battery can be charged.

- In my implementation, when the main bus voltage is above ~13.7 V, if an alternator is engaged, backup battery charging is available. Though one could use a dedicated switch if desired.

- Very low energy loss through the circuit.

- No diodes used as a primary means of current control.

- High side PFET control has negligible loss when enabled (~ 5 mΩ).

- Left SureFly connected to the battery with the highest voltage at all times.

- If the main bus fails to a short or open, the backup battery can still feed the SureFly.

- If the backup battery fails to a short or open, the primary battery can still feed the SureFly.

- Left SureFly power not interrupted if board loses its ground connection.

- The SureFly still receives power from the battery with the highest voltage.

- Without ground, the backup battery cannot be charged, however the EFIS would indicate the backup battery not being connected to the main bus, alerting the pilot to the issue.

- Redundancy in case of discrete device failure.

- Resistor/diode/transistor failure(s) or disconnects won't interrupt power to the SureFly.

- One PFET in each pair can fail and the circuit will still work at the expected current loads.

- If either pair of PFETs fail, the other pair will continue to power the SureFly. The backup battery will be disconnected from the main bus and the EFIS will indicate the voltage mismatch alerting pilot to the issue.

- Up to three PFETs can fail and the SureFly will still receive power.

- Two Zener diodes are used as voltage sensors such that a failure of one can be well-tolerated.

- Can tolerate excessive voltage inputs.

- PFETs and NPNs are tolerant to 40 V. With a 1 kΩ current limiting resistor, the Zener is tolerant to well above 40 V. This is above the ~30 V maximum of most of the onboard avionics.

- Can power other devices directly from the backup battery.

- Allows for power up of the EFIS and AHRS before engine start.

- Allows for monitoring the backup battery voltage.

- Fuses to protect circuit board and associated external connections.

- SureFly fused with on-board 10 A.

- EFIS/AHRS output fused with-onboard 5 A.

- Backup battery input is fused with on-board 20 A.

- Main battery input wire is fused at 30 A very close to the main battery.

- LEDs to indicate circuit state (useful only for testing on the ground):

- Red LED indicating when the main bus exceeds 13.7 V.

- Green LED indicating when backup battery charging enabled.

- Moisture/oil impervious.

- Circuit board coated in acrylic and mounted in a water resistant box.

- All copper traces must be of adequate dimensions for carrying expected current loads.

- Minimum of parts and none specialized.

Here is the circuit board I eventually designed to fit all my criteria. This was my fifth revision of the design and is my final design. I used KiCAD for the layout and OSH Park for board fabrication. This CAD model shows the fuses installed. The schematic is shown further below.

The below shows the board during

bench testing (technically, this is kitchen table testing). The green LED shows when an "ALT FIELD" input to the board is enabled (active high) and the backup battery can receive current from the main bus for charging. The

red LED shows when the main bus is above about 13.7 V and the "ALT FIELD" input is enabled. That threshold

ensures that the backup battery is isolated from the main bus when the

main bus voltage is too low, thus preventing the backup battery from

powering the main bus.

The schematic is shown below. Paired PFETs are used for redundancy and load balancing (though the latter isn't needed given the specs of the PFETs). The PFETs are connected such that, when not enabled, their body diodes always allow the left SureFly access to the battery with the highest voltage and prevents the backup battery from powering the main bus and the main bus from recharging the backup battery. Thus the left SureFly is always energized regardless of the board's state (i.e., no matter the "ALT FIELD" input or main bus voltage).

When the main bus exceeds about 13.7 V, the Zener breaks down, allowing Q6 to turn on but only if Q7 is also on (which itself only turns on if an alternator is selected with the main bus voltage > 13.7 V). At that point all the PFETs turn on, bypassing their lossy body diodes, directly connecting the main bus to the backup battery for charging. Thus the backup battery can never power the main bus when the main bus voltage is below 13.7 V, a value well above the nominal voltage of the backup battery.

The 1k-ohm resistor between the Zener and the base of Q6 is to limit the current in the Zener. This resistor will slightly raise the threshold of the Zener's breakdown voltage. The value of that resistor can be selected to increase the Zener's breakdown a few tenths of volts and/or compensate for tolerance variations in individual diodes. In my case, 1k was the ticket.

Running through scenarios for an isolated failure of the Zener diode in the schematic above:

- Zener fails to open circuit:

- Surefly remains connected to the battery with the greatest voltage.

- The backup battery cannot be connected to the main bus for charging.

- This state will be indicated on the EFIS by the backup battery being a lower voltage than the main bus voltage.

- Zener fails to short circuit:

- Surefly remains connected to the battery with the greatest voltage.

- Main bus voltage > 13.7 V:

- Regardless of alternator operation status, this is not an issue since the main bus voltage exceeds the nominal voltage of the backup battery.

- EFIS indicates that backup battery voltage is lower than main bus voltage.

- Main bus voltage < 13.7 V (e.g., alternator off)

- The upper PFETs cannot be turned on since the Zener diode on the alternator switch board (explained later below) is not in breakdown so the "ALT FIELD" input is not enabled. Thus the upper PFETs' body diodes prevent connecting the backup battery to the main bus.

- EFIS indicates that backup battery voltage is different than the main bus voltage.

- Red LED on circuit board is illuminated even when the voltage on the board's "ALT FIELD" input is artificially forced below 13.7 V. This is an indication of Zener being shorted and is part of my condition inspection check.

Below is the CAD image of the box design. It includes integrated standoffs for

the circuit board. Four single screws are intended to pass through the

battery tray, circuit board and cover to fully capture and mount the assembly. The design uses a Molex

connector on the side to pass the wires through the side of the box.

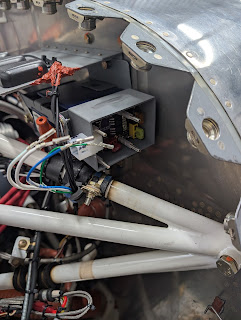

Below is the board installed on the side of the backup battery tray in the aluminum 3D printed box. I will later wrap the Molex joint with silicone tape for a reasonable seal.

The circuit board is encased in acrylic to

help protect it from moisture/oil. Two additional wires were pulled

through an existing firewall pass-through. These wires were for the

alternator (field) select line and connection directly to the backup battery

(to power the left EFIS and AHRS if needed and to monitor the backup

battery voltage). So a total of 5 wires go to the circuit board: Backup battery, main battery, left SureFly, auxiliary power out for EFIS/AHRS and alternator select line. All wires are fused nearest their sources of power as appropriate: Three of the fuses are on the circuit board (backup battery, left SureFly and auxiliary power out), whereas the main battery wire is fused close to that battery and diodes current limit the alternator select line at the panel.

For my own reference, here is the pinout map for that box, looking in to airframe connector.

Since I have two alternators, I needed to create a circuit that allowed a line to go high any time either of the alternators were selected. But also, it should only do that when the main bus voltage exceeds 13.7 V. This is for redundancy in case the main backup battery controller board's Zener diode fails to a short.

This is a very simple circuit and is shown below. The D4 LED (which is green) illuminates when either alternator is selected. The D3 LED (which is red) illuminates only when an alternator is selected and the main bus voltage is greater than 13.7 V. Thus each Zener diode (on this circuit board and the one explained earlier) "cover" for the other in case either fails to a short circuit. Verifying correct operation by viewing the LEDs has been added to my condition inspection.

I designed the circuit to plug in to the back of the alternator select switch (an Otto K1 model K1ABAPCABA) behind the panel so no wires need to be cut or spliced. The back and front of the CAD models of the board are shown below (pictures of the actual board don't show the detail as well). The side with female connectors plugs into the back of the panel switch. The "ALT OUT" line goes to the backup battery circuit board to the corresponding location.

The EFIS and AHRS can be powered by the backup battery if necessary. This allows me to power up the EFIS and AHRS before engine start and/or run the EFIS in flight if the main battery and two alternators become inoperable, understanding that the additional draw reduces the available flight time for the left SureFly. It also allows me to monitor the backup battery voltage, giving me insight as to whether or not it's connected to the main bus (i.e., if the voltage is above its nominal 13.2 V, it's connected to the main bus) and if it isn't, what its loaded or unloaded voltage looks like.

Adding the EFIS and AHRS to the backup battery

places an additional 1.2 Ah load on the battery, giving the left SureFly, AHRS and EFIS

a runtime of 1.5 hours under ideal conditions. Again, switching off the EFIS and AHRS gives the SureFly more than 2x the runtime. And since the backup Horis AI has its own independent backup battery, that possibly make the EFIS and AHRS unnecessary in an emergency.

To consolidate things, I wanted to use the existing switch on my panel that selects if the backup Kanardia Horis AI

is connected to its own, independent, backup battery. That battery is

enabled when its input line goes to ground. So a requisite circuit was

designed with a PFET and isolating diode.

That circuit board was designed to plug in to the back of the Otto K1 switch (model K1AABPCAD) that enables the backup battery for the Horis AI. When the backup battery switch is enabled, the Horis AI is connected to its own backup battery as usual, however the left EFIS and AHRS are then also connected to the EarthX backup battery. However, the left EFIS and AHRS can still be isolated from both the main battery and backup battery through the use of the locking DPDT toggle switch (NKK Switches M2021LL3G01 with a red cap, AT427C) on the left side of the panel. This allows the Horis AI to be enabled and the left EFIS and AHRS to be off if required.

This shows the switch for the left EFIS. In May 2025, I installed a similar switch for the right EFIS.

The CAD models of the front and back of the circuit board discussed above are shown below. The board includes provisions for fuses on the power output lines. A high side PFET design is used for minimal loss when the circuit is enabled. Even though the battery input to this circuit board is fused at 5 A from the battery, I added separate fuses for the EFIS (3 A) and AHRS (1 A). The sockets for those are shown on the bottom left of the front of the board.

The

left EFIS

can then monitor the voltage of the backup battery and I also connected

that power line to an analog input on the right EFIS so it too can

monitor the voltage. Thus, visual and aural anunciations are available if the backup battery voltage is below a programmed threshold and the backup battery voltage can be checked prior to engine start.

Screenshot from the right EFIS is shown below

(immediately following a Vx climb, hence the OilT and CHTs). The

efficacy of the low RDS

PFETs in my design is apparent as the main bus and the backup battery

are at the same voltage when the alternator is enabled and the main bus

voltage is above 13.7 V. Again, both EFISs are programmed to provide me a verbal and visible alert when the backup battery voltage indicates that it is disconnected from the main bus.

Finally, the aircraft's simplified high level electrical diagram now looks like the below.

Circuit boards parts list:

- Schottkey diode: Keyocera AVX SD1206S040S2R0

- PFET: Infineon Technologies: IPP120P04P4L03AKSA2

- Quick connect tabs, 0.25": Keystone Electronics

- Resistor 10 k: Panasonic Electronic Components ERJ-8GEYJ103V

- Resistor 1k: Panasonic Electronic Components ERJ-8GEYJ102V

- Transistor: onsemi MMBT2222ALT1G

- Zener 13 V: Microchip Technology 2EZ13D5

- LEDs: Lite-On, Inc.

- Red: LTST-C150KRKT

- Green: LTST-C150KGKT

- Fuse sockets: Keystone Electronics

wow

ReplyDelete