I really like the grinder I got to replace the original one. It is a beast. But it shook the whole house when running. Wheel dressing didn't help. The wheels were on so tight, I could only get one off. The comments on Amazon were quite favorable towards the balance of this grinder, so I'm going to exchange it for another. I feel bad since my Amazon Prime membership means they do 2 day shipping. The extra plywood from the tables I built will probably be used for a dedicated grinder table so my drill press, band saw and other tools don't die from vibration.

Turns out the Scotch-Brite wheel I got is 1" thick and the grinders I've had so far can only handle 3/4" wheels. Whoops. Apparently these things aren't standardized. Live and learn. It's not that big a deal. Just means that I won't have the wheel cover on, unless I want to buy another wheel (link no longer works) (and, it's far cheaper there).

Speaking of my new drill press with the wobbly bits, I bought a ball joint separator from Harbor Freight Tools to remove the chuck, thinking that there might be some debris that got stuck on the spindle or in the shank. Cleaning both didn't help. After closer inspection, turns out that jaws in the chuck are not straight. Going to call Sears tomorrow to see if they'll send me a new chuck. I already threw away all the packaging, plus they no longer carry that model even though I bought it 17-Feb-13. It does have a lifetime warranty, so I could take it to the store and have them deal with it.

Turns out the Scotch-Brite wheel I got is 1" thick and the grinders I've had so far can only handle 3/4" wheels. Whoops. Apparently these things aren't standardized. Live and learn. It's not that big a deal. Just means that I won't have the wheel cover on, unless I want to buy another wheel (link no longer works) (and, it's far cheaper there).

Speaking of my new drill press with the wobbly bits, I bought a ball joint separator from Harbor Freight Tools to remove the chuck, thinking that there might be some debris that got stuck on the spindle or in the shank. Cleaning both didn't help. After closer inspection, turns out that jaws in the chuck are not straight. Going to call Sears tomorrow to see if they'll send me a new chuck. I already threw away all the packaging, plus they no longer carry that model even though I bought it 17-Feb-13. It does have a lifetime warranty, so I could take it to the store and have them deal with it.

In an effort to reduce any RMI, I picked up a low RPM Black & Decker AS6NG Alkaline Cordless Screwdriver for deburring. Also got Shop Fox D3230 Magnetic Vise Jaws, 4-1/2-Inch to prevent marring gripped work, plus the book Standard Aircraft Handbook for Mechanics and Technicians to read when I'm on the road for work.

After reading Mark Cattell's experience deburring the ribs (the link to his site later become invalid and points to a malicious site so it was removed, 17-Feb-18), I'm eying these parts from Avery:

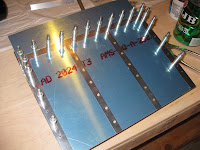

I'm also on the prowl for a rivet organizer. I'm going to need one that has locking drawers and can withstand falling 4 feet onto a concrete floor without exploding into a shower of rivets. There is no doubt that whatever is holding my rivets, it will fall. Turns out, I'm going to go with this idea. It's just genius. I'll just cut the labels from the bags and tape them to the bottles.