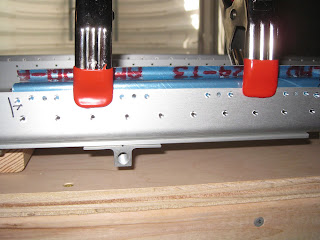

I put in all of the nutplates called for in Section 13. I used clamps to hold them in position then used the squeezer on every rivet I possibly could.

Twice the squeezer caught the throat of the nutplate (image below), but the damage was so slight, I deemed it not worth correcting.

Here's one case where I wasn't being careful and riveted a nutplate 180 degrees out of alignment. I just drilled out the rivets and replaced it.

Left spar with all flange nutplates installed.

Here are the factory and shop ends of the rivets holding a spar doubler plate on the right spar (before I banged on the rivets a second time). I used masking tape to hold the rivets in prior to banging them. Turns out that the cupped set stays in place easier that way (I learned that unintentionally). But, one rivet got a little smiley.

According to

MIL-STD-403C, page 10, "

5.2.7.5 Marring of the manufactured head. A cut or ring caused by the riveting equipment used shall be acceptable on non-flush rivets providing the depth of the cut is not greater than one-fourth of the head height." So, I'm okay with that. I would probably make things worse trying to drill out a AN470AD4-6 rivet anyway. The

2x gun takes about 60 psi to bang these guys in.

Interesting stress lines around the base of the aluminum on the shop end. Turns out this is the

anodized layer.

And then I went over those rivets a second time to square up the shop ends. When I did that, I had removed the masking tape, thus I introduced smiles not just on the rivets, but the spar itself! No bueno.

Here are the fuel tank nutplates ready for riveting on the root of the spar. These were difficult for me to rivet. In fact, I had to drill out four since I set their rivets with the nutplate not flush. You can see the primer I put down over the rivets that had smileys near them on the spar. That was necessary after I sanded out the spar nicks.

Then the countersinking on the fuel tank nut plates. These have to be deep to accept the fuel tank attach screws (AN509-8R8) and dimpled fuel tank skin. I used the digital calipers to make sure I was in spec as called for in the plans. I was 0.36" OD and 0"21 ID, exactly one hundredth of an inch below the max spec. Whew! The test fit looked good. Following this, it was a another round of spot priming. I wish the rivets holding the nutplate sat a little lower though. They are barely beyond flush.

And finally (no pics for this), I used the wrong nutplate on the fuel tank nutplates out on the tip of the spars. I used K1000-8D instead of K1000-3. I must have seen the 3 on the plans as an 8. Though the two parts are close in size, they aren't quite the same. I'm glad I noticed they looked different (even though it was after riveting all 8 in) since now is the time to fix it. They had to be drilled out and the countersunk holes primed again. So, turns out I'm getting quite good at drilling out rivets. The good people at Van's parts line are going to recognize my voice soon.